Waste-to-energy, composting, disposal of liquid waste and related services

Acea has expanded its capabilities in managing the final part of the waste cycle, with the aim of recovery, recycling and reuse and, where possible, recovery of energy. Specifically, The Group manages the treatment of municipal solid waste (MSW) and other types of waste (such as green waste from separated waste collection, industrial waste, etc.) for the recovery of material and disposal of residual materials in landfill, the storage, selection, sorting and separation of multi-material waste originating from separated waste collection, such as plastic and metal packaging, for subsequent recovery, the treatment of liquid waste such as leachates and liquid sludge, waste-to-energy the volumes for disposal, the land needed for the disposaland recovery of the waste energy portion, and the production of high quality compost for agricultural use.

The management of solid and liquid waste is performed at plants using advanced technology and in recent years, in order to improve and renew processes and increase recovery of materials and/or energy, some of them have been upgraded or expanded. The Terni waste-to-energy plant is currently undergoing revamping.

The Companies that operate in the business areas referred to, conduct research, also in collaboration with universities and companies operating in the circular economy field. Included in this context is the well-established Acea Smart Comp composting activity carried out by Acea Infrastructure.

Specifically, during 2023, innovative digital solutions were investigated and tested to manage assets, including the “Digital Twin” solution applied to Acea Smart Comp and aiming to implement a predictive maintenance system for the compost bins. The development of the composting process is supported by the University of Tuscia, where composting bins were installed and introduced in 2022 on a loan-for-use basis for experimental purposes. The standard system was utilised to replicate the research group’s experiment on a broader scale, and in a controlled environment.

In 2023, with the launch of the Call 4 Ideas tender, Acea submitted two proposals to the Lazio region regarding the adoption of virtuous solutions, including Acea Smart Comp, directed at creating environmental and circular communities, seeking to extend the life cycle of resources and materials, and implementing business, circular consumption and climate neutral models, as well as implementing Nature Based Solutions (NBS).

Furthermore, with a view to adding value and recovering waste from industrial processes, in the scope of the collaboration between Acea Infrastructure and the Chemistry Department at the La Sapienza University in Rome, a study was launched to identify possible ways to add value to the waste from the screens at urban wastewater treatment plants.

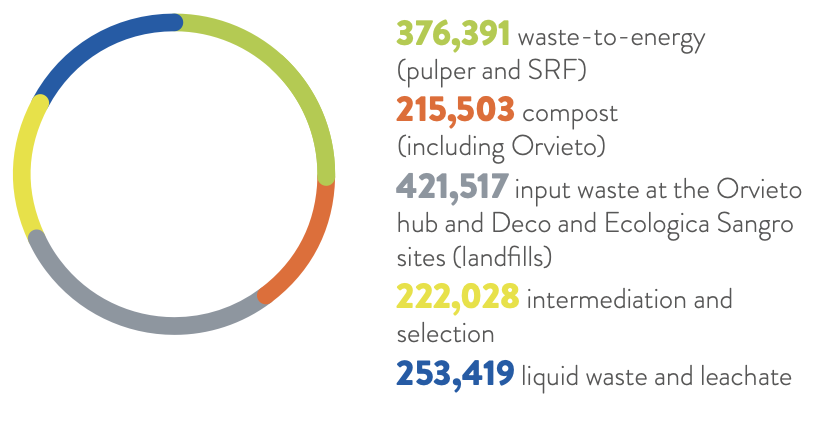

Chart no. 53 illustrates the types of processing and recovery of materials or energy for the Environment Business.

Chart no. 53 – Incoming volumes of waste managed by type of plant/activity (t) (2023)

WASTE-TO-ENERGY

In addition to the activities described of solid and liquid waste treatment and anaerobic-digestion lines at composting sites, Acea Ambiente also manages the waste-to-energy process through the plants of San Vittore del Lazio and Terni. The two plants are operated according to the certified Environmental Management Systems and registration with the European EMAS III scheme (see also Corporate identity, Management systems). For the second consecutive year, in 2023, the waste-to-energy plant at San Vittore del Lazio received the EMAS award at Ecomondo, for the best innovative project for energy from renewable sources, thanks to the extension of the capacitors on the waste-to-energy plant’s Line 1.

Based on circular economy logic, the primary objective is to recover as much material as possible. In 2023, the volume of waste leaving the system was at 23% compared to the waste-to-energy volume, ensuring a reduction in the volumes that needed to be disposed of and in the and use needed for this purpose. The second objective is the recovery of energy from waste, which provides both energy and economic benefits - see Chart 52 and Table 55 in this regard.

In its current configuration, the San Vittore del Lazio plant is the largest in the Lazio Region and plays an important role in the management of municipal waste, both for the advanced technologies used for its construction and for its considerable treatment potential196. It is composed of three independent waste-to-energy lines designed to be fed with Solid Recovered Fuel (SRF), with the following characteristics:

- 52 MWt of thermal power for line 1 and 56.7 MWt of installed thermal power for each of the other two lines, for a total thermal power of approximately 165 MWt

- 13.9 MWe of electric power for line 1 and 17.5 MWe for each of the other two lines, for a total power of approximately 49 MWe;

- approximately 400,000 t/year of SRF, sludge and other waste at full treatment capacity.

In 2022, the Lazio Region issued Resolution no. G14621 to create a fourth waste-to-energy line, enabling the complete processing of waste entering the plant in the case of shutdowns for upgrading or scheduled maintenance, as well as treatment of sewage sludge in compliance with the indication of the Waste Management Plan approved by the Lazio regional authority. In the second half of 2023, the award notice was issued for the design, construction and commissioning of the aforementioned line, with the executive design phase started, which should be completed in 2024. Work will extend up to 2026, and operations should start in the second half of that year.

In 2023 294,174 tonnes of waste were processed by the waste-to-energy plants and approximately 249.7 GWh of electricity was generated, which was in line with 2022 production, at 251.3 GWh.

Table no. 57 – The San Vittore del Lazio waste-to-energy plant: operating data (2021 - 2023)

| u. m. | 2021 | 2022 | 2023 | |

|---|---|---|---|---|

| incinerated fuel | t |

307,391 |

289,550 |

294,174 |

| gross electricity produced | GWh |

267.74 |

251.26 |

249.70 |

| conversion efficiency (*) | kWh/kg CSS |

0.87 |

0.87 |

0.85 |

(*) Relationship between gross electricity produced and quantity of SRF converted to energy.

Revamping work got underway in July 2023, at the Terni plant aimed at bringing the waste-to-energy system in line with the new Best Available Techniques (BAT) set by legislation. These should be completed in May 2024, when the plant will restart operations. The plant comprises a waste-to-energy line with the following characteristics:

- 52 MWt of thermal power installed;

- 13.6 MWe of electrical power installed;

- 120,000 t/year of pulper waste (paper mill waste resulting from the pulping of waste paper), as the maximum potential for incoming waste.

The waste-to-energy plant is equipped with photovoltaic systems, the primary system on the pulper waste pre-treatment area and a secondary system on the adjacent building, which in 2023 generated approximately 436 MWh of electricity, with around 55% consumed on site and the remainder sold to the grid, in line with previous years.

In 2023, waste-to-energy for 82,217 tonnes of paper mill pulp was undertaken, producing approximately 71 Gwh of electricity, which was down on the 2022 figures (-18% energy production), also due to the start of the revamping work at the plant.

For data on the emissions of both waste to energy plants see the chapter Air emissions, in addition to the data reported in the Environmental accounts.

Table no. 58 – Terni waste-to-energy plant: operating data (2021 - 2023)

| u. m. | 2021 | 2022 | 2023 | |

|---|---|---|---|---|

| waste-to-energy paper mill pulper | t |

99,730 |

97,796 |

82,217 |

| gross energy produced | GWh |

88.67 |

85.81 |

70.78 |

| conversion efficiency (*) | kWh/kg pulper |

0.89 |

0.88 |

0.86 |

(*) Relationship between gross electricity produced and quantity of pulper waste converted to energy.

For information on the projects to recover sodium bicarbonate and calcium chloride dihydrate from the treatment of residual sodium carbonate (RSC), as well as on the treatment of fly ash and the recovery of mixed plastics, see the section The Commitment to Research and Innovation in the Institutions and Business chapter.

INTEGRATED WASTE TREATMENT

The company Orvieto Ambiente197, in Umbria, manages an important hub system for waste treatment, the recovery and disposal of waste, ensuring the integrated cycle of municipal solid waste and equivalent materials, produced by all municipalities in the province of Terni. The landfill site is also authorised to receive special waste. The Orvieto Ambiente hub includes the mechanical biological treatment of municipal solid waste, composting and refining of the organic fraction of the sorted waste and disposal in landfills. These activities take place in accordance with the certified Management Systems (see the section Management systems in Corporate identity), with the goal of maximising recovery of materials (production of high-quality compost) and supporting both the production of renewable energy (utilising biogas produced for energy) and, as far as possible, the reduction of waste sent to landfill.

As mentioned above, there are beehives at the hub, which are use to biomonitor the environment by sampling wax, honey and bee matrices, with public educational events planned aimed at local communities. Total waste entering the plant in 2023, was 99,513 tonnes, of which 60% (approximately 59,700 tonnes) was sent to landfill, marking a 71% improvement on 2022. The remainder was almost entirely sent to the anaerobic digestion and composting section of the treatment plant for the production of biogas and compost. The end product resulting from the aerobic process is refined and subsequently analysed for its chemical and physical classification as high-quality compost, for use as a raw material in commercial growing, environmental restoration, and for maintaining green areas (for more information see the "Use of Compost in Agriculture" box).

There are two plants at the Orvieto Ambiente hub that produce energy supplied respectively by the biogas produced by the anaerobic section at the treatment plant and the biogas produced naturally from the landfill. The latter is collected through a supply network and sent to two internal combustion engines that transform it into electricity, which is then sold to the grid:

- approximately 2.8 Mm3 of biogas and 5.2 GWh of energy were produced at the treatment plant in 2023 (+63% compared to 2022198);

- approximately 7.4 Mm3 of biogas and 11.4 GWh of energy were produced at the landfill site (+20% compared to 2022).

In total, approximately 16.6 GWh of electricity was fed into the grid (for more information see the Environmental Report).

The Orvieto Ambiente hub is also equipped with a photovoltaic plant owed by Acea Produzione, which, in 2023, generated around 580 MWh, which was used entirely for self-consumption on site. The company Deco operates in Abruzzo, where it is responsible for managing its own plants199 and plants owned by Acea Ambiente (such as the Grasciano hub200). In particular,

- a landfill for non-hazardous waste in Casoni (Chieti), divided into four sites with a total capacity of over 900,000 m3, which reached capacity in November 2023;

- a landfill for non-hazardous waste in Colle Cese in the Municipality of Spoltore (Pescara), divided into three sites with a total capacity of over 1,000,000 cubic metres;

- a landfill for non-hazardous waste in Grasciano in the Municipality of Notaresco (Grasciano 2) with an approximate capacity of 480,000 cubic metres.

The first two of the above plants belong to Deco, while the latter belongs to Acea Ambiente. Biogas for the production of electricity is recovered at all three sites. In 2023, Deco’s waste processing plants produced approximately 4.3 MNm3 of biogas201and around 1.4 GWh of electricity.

Deco also operates a Mechanical Biological Treatment (TMB) for Municipal Solid Waste (MSW) in Casoni (Chieti), and recovers materials and SRF. In 2023, TMB treated 252,286 t of MSW, from which 4,101 t of metals and 95,869 t of SRF. Around 53% of the SRF produced was used in cement plants outside Italy instead of conventional fossil fuels, while 47% was used in italian waste-to-energy plants to produce electricity. The facility also has a photovoltaic system on the roof that produced 984 MWh in 2023, of which around 860 Mwh (or 87%) was self-consumed on site by the MBT plant and the remainder was fed into the grid.

Ecologica Sangro also operates in Abruzzo, managing the landfill at Cerratina a Lanciano (Chieti). The Cerratina site includes:

• the landfill (operational since 1995);

• the energy recovery from landfill gas plant (since 2005).

The landfill, classified for “non-hazardous waste” is divided into 3 sites with a total capacity of almost 2,800,000 m3. In 2023, it received 56,197 t of municipal waste.

The energy recovery from gas plant produced from the landfill, has an electrical output of 1,672 kW, producing over 10.7 GWh in 2023 and recovering around 7.9 MNm3 of biogas.

HIGH-QUALITY COMPOST PRODUCTION

The Orvieto Ambiente plant hub produced approximately 4,328 tonnes in 2023; in the scope of the experimentation already underway, a new agronomic programme was shared with the University of Tuscia, on additional crops based on the excellent results that had been achieved202(see the specific information box).

Acea Ambiente203 has two other active composting plants: one in Aprilia, the other in Monterotondo Marittimo. The Aprilia plant can recover up to 120,000 tonnes/year of organic waste, with production of electricity and thermal energy integrated with the pre-existing composting section. After the compost bagging line and the SRF production line (from the waste from the same plant) became operational in 2022, transferring the waste to the San Vittore del Lazio plant, in 2023, the Lazio Region authorised204 the implementation of additional improvements at plant and management level, which will make the plant more efficient.

The Monterotondo Marittimo plant has a recovery capacity for the organic fraction of municipal solid waste, garden waste (grass cuttings and material from pruning), and sludge, of 70,000 t/year. Anaerobic digestion and composting facilities are active at both sites, enabling the recovery of electricity and thermal energy. For details on the quantities of biogas and energy produced, see the Energy Business chapter and the Environmental Report.

In 2023, Monterotondo Marittimo and Aprilia produced around 43,200 tonnes of quality compost.

THE USE OF COMPOST IN AGRICULTURE

At the Orvieto Ambiente hub, studies are currently being conducted with the University of Tuscia to better understand the effects of using compost in agriculture, from a production and responsible consumption perspective. The land adjacent to the plant has been cultivated in this regard, using 0 km compost produced at the plant. Based on the excellent results achieved, the collaboration with the University of Tuscia was renewed in 2023 for the two-year period 2023-2024, which was also confirmed with the EMAS award won in 2022. The objectives include understanding the role of compost in the chemical, physical and biological fertility of the soil and its repercussions on certain crops relevant to the Province of Terni and Viterbo, and to circulate the outcomes achieved.

INTERMEDIATION AND TRANSPORT OF WASTE

In 2023, Aquaser, which loads, transports, recovers and disposes of waste produced by treatment plants, managed around 395,000 tonnes of waste (of which, approximately 250,000 t of liquid waste and about 145,000 t of solid waste). With regard to intermediation, during the year Aquaser took charge of approximately 161,000 tonnes of waste, of which 127,000 tonnes of sludge is attributable to the Group’s water companies205, and in particular approximately 75,000 tonnes to Acea Ato 2, AdF, Acea Ato 5. The dried and dewatered sludge coming from the three Companies was sent to the following end destinations:

- 66.7% to material recovery operations (pretreatments aimed at agricultural use and composting);

- 16.8% to recovery of energy (waste-to-energy);

- 16.5% for disposal.

Also this year, due to regulatory constraints direct spreading was not used in agriculture.

Aquaser used its own means to transport approximately 38,200 tonnes of non-hazardous waste. Of this, about 33,200 t referred to transporting waste produced by the Group’s water companies, Acea Ato 2, Acea Ato 5, AdF, Umbra Acque, Acque and Publiacqua, where Aquaser also acts as a broker. The remaining 5,000 t referred to the transporting of non-hazardous waste produced by third parties or other Group Companies (Acea Ambiente).

SELECTION AND SEPARATION OF MULTI-MATERIAL WASTE

The Demap plant, located in the province of Turin, carries out selection and implementation of recycling for plastic and plastic/metal packaging. In particular, it handles the storage, selection, sorting and separation of single and multi-material waste originating from separate waste collection, such as plastic material and metal packaging, for subsequent recovery. The Demap plant is affiliated with the Corepla Consortium, a group of companies established pursuant to Italian Legislative Decree 22/1997 to organise and manage post-consumption plastic packaging, and performs its activity on the basis of a contract for the selection of waste plastic packaging with the Consortium itself. In 2023, approximately 30,150 tonnes of material entered the plant and was processed for separation and recovery.

TREATMENT OF LIQUID WASTE

Acque Industriali carries out brokering and liquid waste treatment services for private and public companies, as well as activities related to the integrated water cycle, mainly consisting of the recovery and disposal of organic sludge, through the management of several platforms. In 2023, the sites at Poggibonsi, Pisa Nord and Pontedera were inactive206; treated waste decreased and amounted to approximately 25,205 tonnes of liquid waste (-50% compared to 2022). In addition, the Company provided brokerage services for approximately 30,000 tonnes of waste during the year (-19% compared to 2022).

Acque Industriali uses technologies that support recovery of raw materials contained in waste, energy saving and the efficient use of resources, such as stripping/absorption of ammonia in a closed cycle that enables the recovery of ammonium sulphate, which can be used as an agricultural conditioner, of which 22,000 kg207 was produced in 2023. The Company also provides services for the design, creation and management of plants for the treatment of wastewater for third parties, decontamination of polluted sites and environmental consulting for the management of plants.

For details on the incoming waste, the types of resources used, the waste produced and other specific information, see the Environmental Report.

The Berg plant is a polyfunctional platform for the storage and processing of hazardous and non-hazardous waste, authorised for the sale and brokerage of waste and the creation of plants for treatment and processing of liquid waste.

Specifically, the plant has two departments: storage and treatment of liquid waste and storage and treatment of solid waste. In 2023 approximately 131,900 tonnes of waste, both solid and liquid, was processed, with almost zero tonnes of intermediated waste.

The Chiusi plant208 handles the chemical/physical and biological treatment of non-hazardous liquid waste209 and the treatment of sewerage. In 2023 approximately 96,300 tonnes of liquid waste were processed and approximately 86,900 m3 of wastewater.

176 With reference to Decree Law 133/2014 (referred to as Sblocca Italia), the plant has been defined as a strategic structure of primary national interest for the protection of health and the environment, as per Lazio Regional Decree no. 199 of 24/04/2016.

177 https://www.isprambiente.gov.it/it/attivita/certificazioni/files/emas/newsletter/2022/newsletter-emas-n3-2022.pdf.

78 Deco's facilities include a Transfer Point where third-party urban waste collection vehicles transfer the collected waste from their own machines to larger-capacity vehicles, and a depot on the quayside of the port of Ortona, in the Province of Chieti, authorised for the storage of waste for recovery, where the SRF to be shipped is stored, providing several logistical, organisational and environmental advantages. This is not included in the reported data due to its negligible significance.

179 The Grasciano site also includes other plants that have been inactive for several years: a platform for the treatment and energy recovery of waste from separated waste collection, a landfill for non-hazardous waste (Grasciano1) and two waste treatment lines (one for mixed and/or similar waste to produce SRF and the other for the wet organic fraction derived from separated waste collection to produce high-quality compost).

180 The liquid waste treatment facility at Sabaudia is currently inactive and studies, analyses and technical and economic assessments are currently underway to identify possible new industrial uses for the site.

181 The data detailed here for the sake of completeness concerns sludge for which Aquaser has managed the entire supply chain, from loading to transport and final disposal, originating from the following Group Companies: Acea Ato 2, Acea Ato 5, Acquedotto del Fiora, Umbra Acque, Publiacqua, Acque and Acea Molise.

182 As well as the two platform closures, the platform at Poggibonnsi suspended its activities in June 2021 pending the re-issue of the standard operation permit.

183 (*) On 1 May 2021, Bio Ecologia Srl was merged by incorporation into Acea Ambiente.

184 The quantities of liquid waste authorised for treatment (excluding wastewater) have a maximum limit of 99,900 tonnes/year.